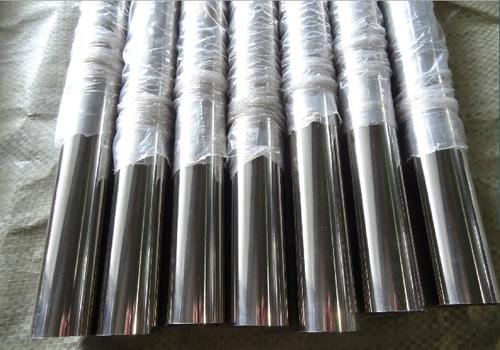

Precautions for stainless steel to prevent rusting

Precautions for stainless steel to prevent rusting

Stainless steel can be divided into many categories, the commonly used methods are austenite, ferrite, duplex, martensite, precipitation hardening, etc. Only austenitic stainless steel is non-magnetic, but this stainless steel accounts for the vast majority of the stainless steel market. Other steels are magnetic, which is why magnetism is used to distinguish stainless steel in China's domestic market. But other types of stainless steel are magnetic. For example, many times you go to a restaurant use magnets to try out shiny stainless steel knives forks. They are usually magnetic. In fact, it is likely that martensitic stainless steel automobile exhaust pipe stainless steel are also magnetic. It is ferrite. Austenitic stainless steels usually require the addition of nickel. At present, the price of nickel in the world is very high. Therefore, one of the main development trends of stainless steel is how to save nickel. A good method is to develop ferritic stainless steel duplex stainless steel. Therefore, there will be more stainless steel magnets in the future.

In fact, stainless steel will also rust, but the characteristics of stainless steel materials are considered in the selection of materials. The misuse of stainless steel will lead to abnormal corrosion of stainless steel. Under general environmental conditions, the steel added with some elements will rust as long as it is qualified stainless steel. This is because stainless steel contains an important alloy element Cr, which can form a dense passive film on the surface of stainless steel to protect the stainless steel. It is easy to corrode.

we need to pay attention to some cases, stainless steel will also rust. Local corrosion occurs due to the damage of the surface passivation film. There are many types of local corrosion, including pitting, crevice corrosion, intergranular corrosion, stress corrosion galvanic corrosion. The causes of these two kinds of corrosion are the same, they are closely related to Cl -. In order to avoid this situation, please pay attention to avoid stainless steel in Cl - environment for a long time. The second is to pay attention to the cleanliness of the stainless steel environment, so as to avoid being dirty scratch on the surface of stainless steel. A new passivation film can be formed on the stainless steel surface after scratch. However, the newly formed passivation film is usually fragile, the scratch is easy to form geometric gap, which is easy to produce crevice corrosion rust.

So how to avoid stainless steel rusting? Pay attention to avoid using stainless steel in Cl - environment for a long time, then pay attention to the cleanliness of stainless steel environment to avoid dirt, to avoid scratching on the surface of stainless steel. A new passivation film can be formed on the stainless steel surface after scratch. However, the newly formed passivation film is usually fragile, the scratch is easy to form geometric gap, which is easy to produce crevice corrosion rust.