Advantages of seamless stainless steel pipe?

Advantages of seamless stainless steel pipe?

At present, continuous casting is mainly used in stainless steel production. The caster is mainly vertical curved. Compared with the traditional ingot rolling billet, the continuous casting billet of stainless steel has better properties quality, the metal yield is increased by 10% - 15%, the cost is significantly reduced. At present, hot extrusion is the main process for manufacturing seamless stainless steel pipe. With the gradual elimination of hot-rolled steel pipe plant, extrusion plant is becoming the main production equipment of stainless steel seamless steel pipe in the world.

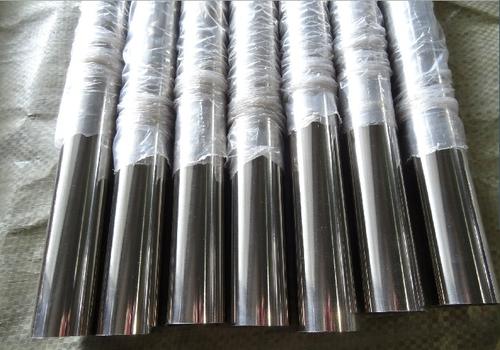

Most of these extrusion units are used for the manufacture of steel tubes, except for a small amount of profile extrusion. The main variety is stainless steel seamless steel pipe. Compared with the rolling process, the feature of extrusion process is that the metal deformation process will bear three pressures. Under such stress conditions, the compression stress of various types high deformation resistance stainless steel tubes can form satisfactory deformation in all directions, the internal external surface quality metallurgical structure state can be achieved.

Stainless steel pipe is made of stainless steel pipe by extrusion process. Continuous casting billet can be used as raw material directly. The quality of stainless steel tube is stable flexible to replace. Hot extrusion stainless steel tube can be directly manufactured used in production. There are various types of profiled stainless steel tubes, but the disadvantage of the extrusion method used to manufacture stainless steel tubes is low yield.

In order to improve the productivity of stainless steel pipe, some manufacturers optimize the production process. If the products with high requirements are usually pre drilled, the hydraulic perforator is used to enlarge the hole squeeze into the production process of the pipeline, while the requirements of the general cold processing raw material pipeline are different according to the actual situation. After a large hole is drilled on the billet for large steel pipe extruded into a tube, it is directly put into the extruder to extrude the tube. Obviously, the stainless steel seamless steel pipe plant uses extrusion method to produce finished pipe provides cold working. Barren pipe is a relatively economic cost-effective production method for a large number of heat-treated stainless steel pipes abroad.

In addition, cold rolling is the main production process for most cold working stainless steel tubes, while cold drawing is an auxiliary production process. 50% - 80% of the stainless steel tubes are to be cold worked to produce finished products. Therefore, cold working technology equipment will be greatly developed. There are three types of cold working technology, namely cold drawing process, cold rolling process cold rolling cold drawing combined process. In foreign countries, cold rolling cold drawing process are mostly used in cold working of stainless steel pipes.

At present, the cold rolling mill can reduce the large wall thickness large diameter of stainless steel pipe. 80% of the deformation can be completed directly on the cold rolling mill. Cold rolling is used to fix the walls. The outer diameter can meet the production requirements of different specifications varieties.

The advantages of this production process lie in the quality of the finished 304 stainless steel pipe, the high wall thickness surface quality of the pipe, the high accuracy of the outer diameter of the cold drawn steel pipe, the short cold working cycle, the elimination of intermediate degreasing, heat treatment shrinkage. The processes such as opening, straightening pipe consumption are effective in energy saving, can simplify the specifications of various raw materials, so as to expand the production scale.